When it comes to the world of mechanical tools, few materials offer the blend of strength, resilience, and precision quite like high carbon steel. Whether you're a seasoned mechanic, a passionate DIYer, or an industrial engineer, the right wrench set can make all the difference in your efficiency, safety, and overall satisfaction. Today, we delve into the craftsmanship and engineering behind high carbon steel wrench sets — tools designed not just to work, but to endure.

The Soul of the Tool: How High Carbon Steel Transforms Your Repairs

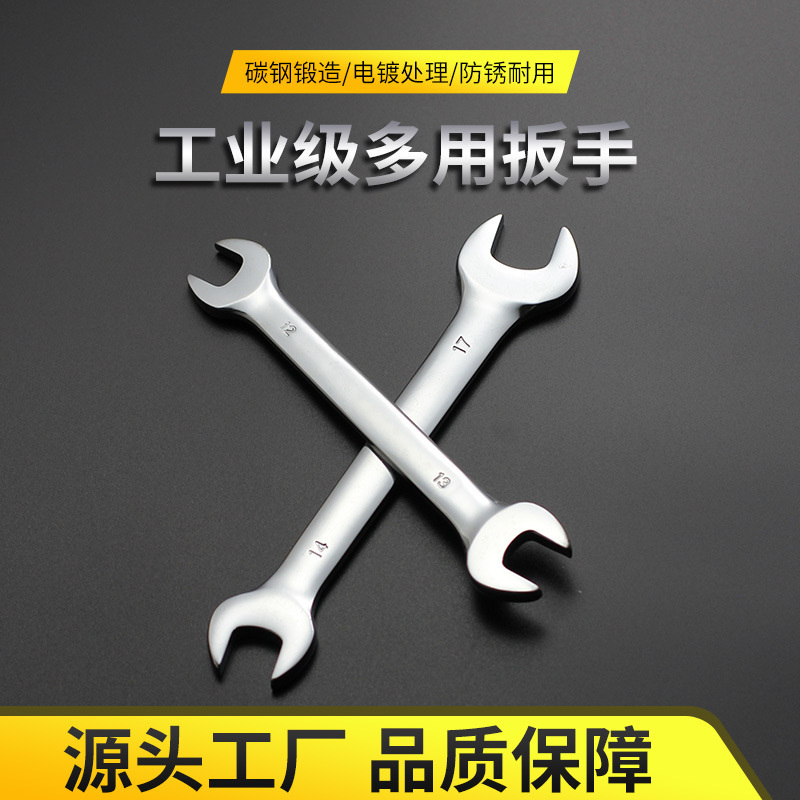

High carbon steel has long held a revered place in the hierarchy of industrial materials. Known for its impressive tensile strength and resistance to deformation, this alloy is the go-to choice for professionals who demand reliability under pressure. Unlike standard steel or chrome-vanadium alloys, high carbon steel wrenches maintain their shape and function even under extreme stress, making them ideal for tasks that require precision torque and durability.

What sets these wrenches apart is their ability to balance hardness with a degree of flexibility. This balance ensures that while the tool remains tough enough to withstand repeated use, it doesn’t become brittle or prone to cracking. In real-world use, this translates to a wrench that grips tighter, lasts longer, and resists wear far better than its lower-grade counterparts.

The Art of Forging: Why Forged Tools Mean Quality

Forging is more than a manufacturing process — it's a tradition of strength. The forging process involves heating the metal and shaping it under intense pressure, which aligns the grain structure and eliminates internal voids. This results in a tool that’s significantly stronger and more durable than cast or machined alternatives.

In practical terms, forged high carbon steel wrenches can handle higher torque without slipping or rounding off nuts and bolts. They’re less likely to snap during high-stress applications, making them essential for automotive repair, construction, and heavy machinery maintenance. The difference is not just in performance, but also in longevity — a well-forged wrench can last a lifetime with proper care.

From Shine to Substance: The Mirror Matte Finish That Elevates Every Tool

While functionality is paramount, aesthetics and usability also play a role in the user experience. The mirror matte finish found on premium wrench sets is more than just visually appealing — it serves a practical purpose. Achieved through a combination of polishing and chemical treatment, this finish reduces glare while maintaining a sleek, professional appearance.

Beyond its beauty, the mirror matte surface enhances grip by offering a slightly textured tactile feel. It also resists fingerprints and corrosion better than glossy finishes, preserving the tool's appearance and performance over time. Users often report a sense of pride and professionalism when using these tools, which can subtly influence confidence and workmanship.

One Set, Endless Possibilities: Multi-Specification Design for Every Task

Modern wrench sets are no longer one-size-fits-all. The inclusion of multiple specifications ensures that users have the right tool for any job, from delicate electronics to rugged automotive components. Whether you're assembling furniture at home or repairing a transmission in a workshop, having a variety of sizes and configurations at your fingertips saves time and reduces the need for multiple tool purchases.

These sets are particularly useful in multi-industry environments. A mechanic might rely on larger sizes for engine work, while a plumber could use smaller, tighter wrenches for pipe fittings. The versatility of a well-designed set means that it grows with your needs, adapting to whatever challenge you face next.

Flat Ribbed Heads: A Small Innovation with Big Impact

At first glance, the flat ribbed head design may seem like a minor detail — but in practice, it makes a world of difference. The flat profile allows the wrench to fit into tight spaces where a traditional hexagonal head would struggle. Meanwhile, the ribbed texture enhances grip, reducing the chance of slippage and increasing control.

This design is especially beneficial in confined mechanical environments, such as engine compartments or plumbing walls, where precision and access are limited. Users consistently praise the ease of use and added security these features provide, especially during repetitive or high-torque tasks.

Craftsmanship Meets Innovation: The Spirit Behind Every Wrench

Beneath the polished exterior and precise engineering lies a deeper story — one of craftsmanship and dedication. While modern manufacturing has embraced automation, the best tools still carry the touch of human care. Each edge,刻度, and chamfer is meticulously designed and tested to ensure it meets the highest standards of performance and ergonomics.

Brands that stand the test of time understand that trust is built through consistency and attention to detail. From the weight of the tool in your hand to the clarity of the markings, every element contributes to a user experience that’s intuitive, satisfying, and safe.

Your Next Big Project Deserves the Right Tools

Whether you're a weekend DIY warrior, a full-time mechanic, or an engineer in a high-stakes industrial setting, the right wrench set is more than just convenience — it's an investment in efficiency and safety. For casual users, a compact set with essential sizes is perfect for home repairs. Meanwhile, professionals benefit from larger, more comprehensive kits that cover a wide range of applications.

Choosing the correct configuration depends on your usage frequency and the nature of your work. High-impact tasks demand heavier, more robust tools, while precision work calls for lighter, more finely calibrated wrenches. No matter your field, there's a high carbon steel wrench set designed to meet your specific needs.

Looking Ahead: The Future of Tools and Materials

As industries evolve, so too do the tools we rely on. While high carbon steel remains a benchmark for strength and durability, new materials like titanium alloys and composite blends are emerging in specialized applications. Yet, the fundamental principles of performance and reliability remain unchanged.

With the rise of smart tools and digital integration, the future may bring connected wrenches with torque sensors or digital readouts. However, the core value of a well-made, manually operated wrench remains irreplaceable. In a world of rapid technological advancement, the simplicity and effectiveness of a high-quality forged wrench continue to stand strong.

Conclusion: Choose Strength, Choose Precision

In the realm of mechanical tools, few investments offer the lasting value of a high carbon steel wrench set. From the forging process to the mirror matte finish and intelligent design features like flat ribbed heads, every detail is crafted with purpose. These aren’t just tools — they're companions in every project you undertake.

Explore the full range of high carbon steel wrench sets today and equip yourself with the tools that professionals trust. Your next repair, build, or overhaul deserves nothing less than excellence.