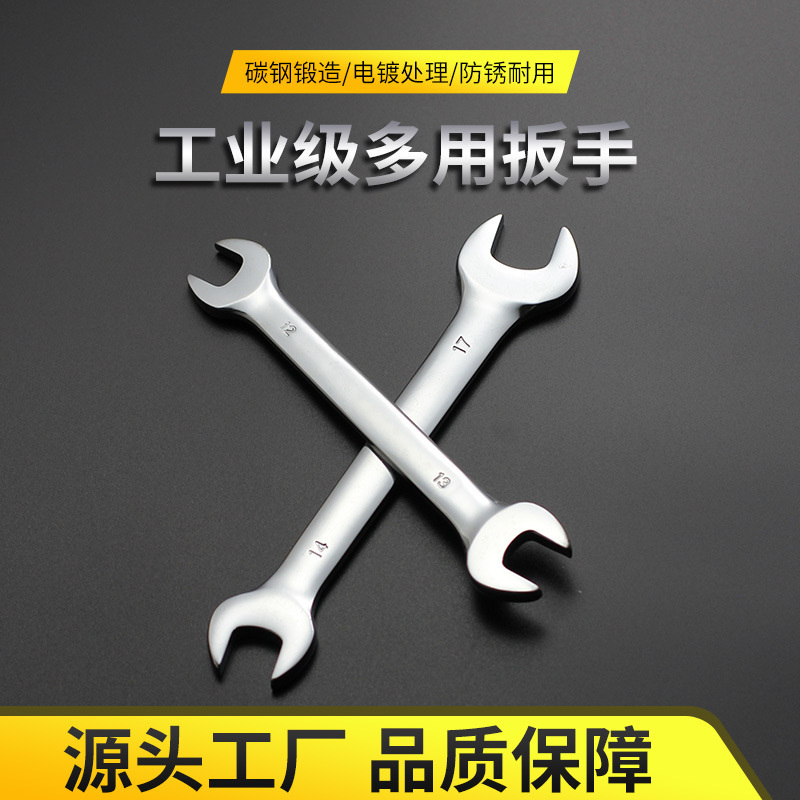

High Carbon Steel Double Head Wrench Set – Wholesale Forged Tools in Mirror & Matte Finish

Precision-forged high carbon steel wrenches with dual mirror and matte finishes – engineered for performance and durability.

The Metal Art Behind the Tool: How High Carbon Steel Shapes the Soul of Modern Wrenches

Every great tool begins not in a factory, but deep within the earth. Our High Carbon Steel Double Head Wrench Set starts its journey as raw ore, transformed through a meticulous metallurgical process that enhances strength, resilience, and fatigue resistance. High carbon steel, known for its superior hardness and tensile strength, undergoes controlled heating and quenching to achieve an optimal balance between toughness and wear resistance—making it the gold standard for professional-grade hand tools.

Forging is where true craftsmanship takes shape. Unlike stamped or cast alternatives, each wrench is forged under immense pressure—one hammer strike at a time. This grain-flow alignment increases structural integrity, reducing the risk of cracking under torque. The result? A tool built to last decades, not just jobs. It's this “one blow at a time” philosophy that separates mass-produced imitations from genuine forged excellence.

Forged construction ensures internal grain alignment for maximum durability and shock resistance.

Aesthetics meet function in our dual finish design. One end shines with a polished mirror finish—resistant to corrosion and easy to clean—while the other features a refined matte surface that minimizes glare during overhead work. Together, they represent more than visual contrast; they offer practical advantages tailored to real-world conditions.

The Intelligence of Dual Heads: Why Two Sizes Outperform One

In tight engine bays or cramped utility panels, space is the enemy of efficiency. That’s where the brilliance of the double head design comes into play. Flip the wrench, switch sizes—no need to swap tools. Whether you're loosening a stubborn bolt on a motorcycle frame or adjusting fittings in HVAC ductwork, having two precisely machined openings on a single handle drastically reduces downtime and clutter.

Imagine working beneath a car chassis, where every inch counts. Instead of fumbling through a toolbox, you simply rotate your wrist. From 10mm to 12mm, 14mm to 17mm—our multi-specification sets cover common fastener sizes used across automotive, bicycle, plumbing, and industrial machinery. This versatility means fewer tools in your kit, yet broader capability.

Dual-size heads enable rapid transitions in confined spaces—maximizing reach and minimizing tool swaps.

From weekend DIYers restoring vintage bikes to maintenance crews servicing heavy equipment, users consistently report faster job completion and reduced physical strain when using double head wrenches. It’s not just about convenience—it’s about workflow optimization.

More Than Just Looks: The Engineering Behind Ribbed Surfaces

The textured ribbing along the wrench handle isn’t merely decorative—it’s a critical safety feature. In oily, greasy, or wet environments, smooth surfaces can slip dangerously. Our flat ribbed pattern provides consistent grip even with gloved hands, preventing slippage during high-torque applications. Compared to flat or fine滚花 (knurled) finishes, ribs offer superior tactile feedback and resistance to palm fatigue.

Surface treatment also plays a role in performance. Contrary to myth, a mirror finish doesn't compromise strength—it actually resists rust and allows easier detection of cracks or wear. Meanwhile, the matte side offers scratch resistance and reduces light reflection, crucial when working under bright shop lights. Both finishes are heat-treated and tested for hardness above HRC 45, ensuring long-term dimensional stability.

Engineered ribbing enhances grip, while dual finishes combine corrosion resistance with anti-glare functionality.

Voices from the Workshop: Who Trusts These Wrenches Daily?

After a full week of daily use in a busy auto repair garage, veteran mechanic Luis noted: “I’ve had cheaper wrenches round off bolts. These didn’t flinch—even on seized exhaust manifolds.” His experience reflects what many professionals value: consistency, reliability, and the confidence to apply force without fear of tool failure.

Diy enthusiasts have shared similar stories. One user documented a late-night motorcycle carburetor rebuild, where a corroded nut finally gave way after repeated shocks—thanks to the precise jaw fit and forged leverage of the wrench. No rounding, no slipping—just clean torque transfer.

Even tool rental companies are turning to wholesale forged sets like ours. With hundreds of tools circulating monthly, durability directly impacts profitability. Lower replacement rates, minimal warranty claims, and higher customer satisfaction make high carbon steel the smart economic choice.

Ideal for wholesale distribution—durable packaging, uniform quality, and scalable configurations.

Wholesale Isn’t Just About Price—It’s a Strategic Advantage

Buying in bulk should never mean compromising on consistency. Our manufacturing process uses automated forging lines paired with manual inspection, ensuring every batch meets the same exacting standards. Small workshops may lack this level of control, leading to unpredictable tool life. When you source from a trusted supplier, you’re investing in predictability.

Inventory management becomes simpler with multi-size combo sets. Rather than stocking dozens of individual wrenches, distributors can offer complete kits that reduce SKU complexity and warehouse footprint. And for brands looking to stand out, customization options like laser-engraved logos, color-coded handles, or metric/imperial markings add value without inflating cost.

The Future of Forged Tools: Where Tradition Meets Innovation

As sustainability gains importance, repairable, long-lasting tools gain relevance. Unlike disposable plastic-handled alternatives, these all-metal wrenches can be reconditioned, extending their lifecycle and reducing waste. In an era of planned obsolescence, that’s a powerful statement.

While smart tools with digital torque readouts exist, there will always be a place for the mechanical simplicity of a well-made wrench. No batteries, no sensors—just pure physics and precision engineering. That reliability is why they remain indispensable in disaster response, remote fieldwork, and emergency repairs.

Looking ahead, we’re exploring ways to further optimize weight without sacrificing strength—using advanced heat treatment and selective material removal—to create next-generation wrenches that are lighter, stronger, and smarter by design.

The High Carbon Steel Double Head Wrench Set isn’t just another tool. It’s the fusion of ancient forging wisdom and modern engineering—crafted for those who demand excellence, one turn at a time.